What rules should PCB assembly processing follow?

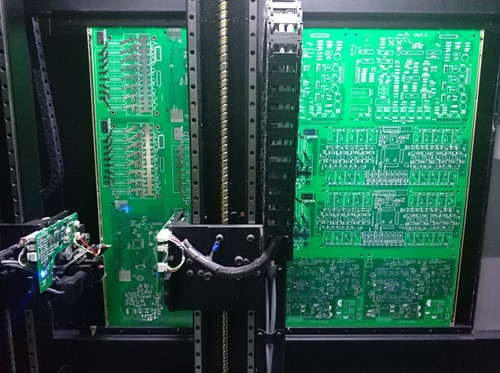

PCBA is the process of SMT on the bare PCB board and DIP plug-in. It involves many elaborate and complex processes and some sensitive components. If the operation is not standardized, it will cause process defects or component damage, affect product quality and increase processing costs. Therefore, in the process of PCBA manufacturing, it is necessary to abide by the relevant operating rules and operate in strict accordance with the requirements.

1. There should be no food or beverage in the PCBA working area. Smoking should be prohibited. No work-related sundries should be placed and the worktable should be kept clean and tidy.

2. The welded surface in PCBA processing must not be taken by bare hands or fingers, because the grease secreted by hands will reduce the weld-ability and easily lead to welding defects.

3. Reduce the operation steps of PCBA and components to a minimum in order to prevent danger. In the assembly area where gloves must be used, dirty gloves can cause pollution, so gloves need to be replaced frequently when necessary.

4. Do not use skin-protecting oils or detergents containing silicone resin, which can cause problems in solder-ability and bonding properties of the coating. A special detergent for PCBA welding surface is available.

5. EOS/ESD-sensitive components and PCBA must be identified with appropriate EOS/ESD markers to avoid confusion with other components. In addition, in order to prevent ESD and EOS from endangering sensitive components, all operations, assembly and testing must be completed on a workbench capable of controlling static electricity.

6. Check the EOS/ESD workbench regularly to make sure that they can work normally (anti-static). The various hazards of EOS/ESD components can be caused by incorrect grounding methods or oxides in grounding connections. Therefore, the connection of the "third line" grounding terminal should be given special protection.

7. It is forbidden to stack PCBA, which will cause biologic damage. Special brackets should be equipped in the assembly face and placed according to the type.

In the process of PCBA manufacturing, these operating rules should be strictly observed and correctly operated, so as to ensure the final quality of products, reduce the damage of components and reduce costs.

PCBbee.com offer precise PCBA quotation in 2 Hours. Quote Now!

Sign In

Sign In Join Free

Join Free