Conventional Factors affecting the PCB board price

There are many factors affecting the PCB board price: The number of layers, thickness, material, order quantity, surface treatment process, copper foil thickness, ink color, line width, minimum aperture, delivery time, etc..

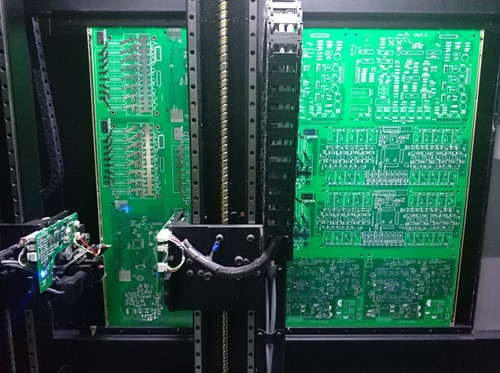

1. The number of layers

PCB board layers represent layers of independent wiring layer. With the gradual development precision of electronic equipment, the requirements for the number of PCB are also improved. At present, we need to use ten layers, twenty layers, and even higher layers board to produce high precision electronic products. PCBbee produces 1-8 layers PCB board.

The 4 layers, 6 layers, or the 8 layers circuit board price are higher than the double-sided board. The 8 layers PCB price is about 4 times the of the double-sided board.

2. Board thickness

According to the application field, PCB thickness requirements are not the same. For example, the chip of bank card only needs 0.1mm thickness circuit board, and the thickness of 2.0mm board is not suitable. PCBbee can produce 0.4mm-2.4mm thickness circuit.

Not be determined only by the laminate thickness, the laminate manufacturer, laminate type jointly affect the price.

3. Materials for PCB board

To meet the IPC standard and customer requirements, pcb need a lot of raw materials in the production process. Raw material include PCB copper clad laminate, ink.

Different types of copper clad laminate price is different, For example: copper clad laminate Rogers (Rogers), PTFE, Arlon (Ya Long) price is 10 times or even several dozen times of FR-4 material.

Different colors, brands of ink price gap is relatively large. For example, the price of matt black ink is about three times as much as that of ordinary green ink.

4. Order quantity

The more the quantity, the lower the price. Because the more order quantity, the higher the utilization rate of raw materials and production efficiency which will eventually led to price drops

5. Surface treatment process of PCB board

According to the application environment and quality requirements of terminal electronic products, the surface treatment process of PCB board is different. The most common are HASL(hot air solder leveling), OSP, Immersion gold(ENIG), Immersion silver, Immersion Tin. PCBbee currently offer surface treatment processes of HASL lead free, HASL with lead, Immersion gold(ENIG). Different surface treatment pcb price are different. The Immersion gold (ENIG) surface treatment cost is higher than HASL(with/without lead).

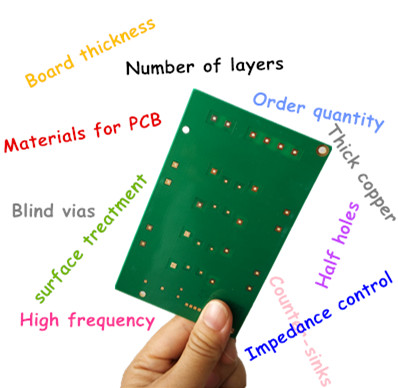

Other factors that affect the PCB price:

PCB special process (such as half holes, high frequency, thick copper(3oz or higher) board, blind vias, impedance control, rigid-flex, Counter-sink, etc.) will affect the manufacturing cost. Usually, the circuit board with a special process will be much higher than the conventional board price.

PCBbee.com can offer pcb online quote, online order,payment online,pcb production status checking, delivery trace service. Try our system to get the most cost-effective PCB board price now.

Sign In

Sign In Join Free

Join Free