PCB Assembly Process Steps

The production process of PCBA is mainly as follows: purchasing materials → solder paste printing → solder paste thickness gauge →mounting machine → reflow welding → AOI → DIP plug-in → wave soldering → cleaning after welding → PCBA function test → product assembly → shipment.

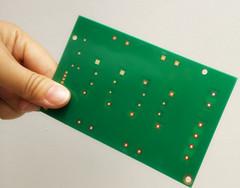

1. Purchasing Material

PCBA manufacturer purchases components and PCB bare boards according to customer orders, and makes pcb stencil and fixtures.

2. Solder Paste Printing

First, the solder paste just taken out from the refrigeration room is thawed and stirred, and then the solder paste printer accurately leaks to the PCB pad.

3. Tin paste thickness gauge

Examine the printing effect of solder paste, check whether there is less tin, missing printing.

4. Mounting Machine

By absorbing components, the SMT machine can accurately mount the components onto the PCB pad.

5. Reflow Welding

The PCB mounted with the components is put into the reflow welding track, and the components are welded through the drying zone, preheating zone, welding zone and cooling zone.

6. AOI Detection

After the PCB is welded, AOI is used to test the welding effect of PCB, and QA sampling is carried out.

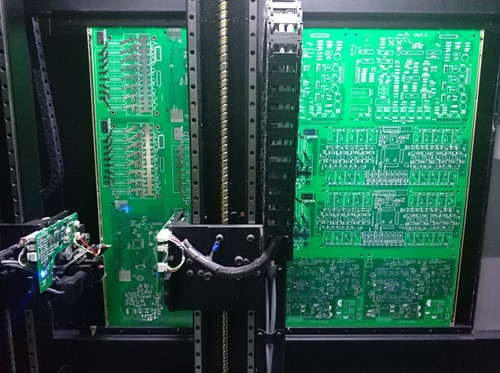

7. DIP Processe

DIP production line workers simply process the plug-in material and insert it into the corresponding position of the board.

8. Wave soldering

Put the inserted board into the wave soldering machine, through spraying flux, preheating, wave soldering, cooling and other steps, realize the welding of PCBA board.

9. Post-weld cleaning

There are many defects in the PCBA boards after wave soldering, which usually need to be repaired and cleaned, and then transferred to the next process after the quality personnel have checked it correctly.

10. PCBA Functional Testing

In PCBA function test, PCBA board should be ICT, FCT, aging test and programming to ensure the normal operation of PCBA function and reduce the later repair rate.

11. Assembly of finished products

After the PCBA board completes the internal function test, the shell of the product is assembled.

12, Shipment

Finally, OQC inspection is needed to confirm the correct delivery.

PCBA is to process an empty PCB board into an electronic product that can be used by users through a series of processes. In the process of production, each step is important, which step has quality problems, which have a great impact on the quality of products.

PCBbee.com offer precise PCBA quotation in 2 Hours! Quote Now!

Sign In

Sign In Join Free

Join Free