Residue on PCBA

The development trend of the electronic information industry has higher and higher requirements on the PCB assembly process, and the reliability and quality of the electronic complete machine products are mainly determined by the reliability and quality level of the PCBA boards. In the process practice and the failure analysis of the PCBA, the residues on the PCBA have a great influence on the reliability level of the PCBA. The following is an inventory of the types and sources of the residues on the PCBA boards.

Residues on PCBA board mainly come from the assembly process, especially the soldering process. Such as flux residues used, by-products of the reaction between flux and solder, adhesives, lubricants and other residues. The potential hazards of other sources are relatively small, such as pollutants and sweat caused by the production and transportation of components and the PCB itself. These residues can generally be divided into three categories. One is non-polar residues, mainly including rosin, resin, glue, lubricating oil, etc. These residues can only be removed well by washing with non-polar solvents. The second category is polar residues, also known as ionic residues, which mainly include active substances in the flux, such as halide ions, and salts produced by various reactions. These residues need to be removed well, and polar solvents must be used. Solvents such as water, methanol, etc. There is also a type of residues with weak polarity, mainly including organic acids and bases from the flux. To obtain good removal of these substances, compound solvents must be used. The basic categories of residues are described in detail below.

1. Residue of rosin flux

The flux containing rosin or modified resin is mainly composed of non-polar rosin resin, a small amount of halide and organic acid, and an organic solvent carrier. The organic solvent will be volatilized and removed due to high temperature during the process. Active substances such as halide organic acids (such as adipic acid) mainly remove the oxide layer on the PCB surface to be welded and improve the welding effect, but in welding, the complex chemical reaction process changes the structure of the residue. The product can be unreacted rosin, polymerized rosin, decomposed activator and activator such as halide, the metal salt produced by the reaction with tin and lead, the rosin that has not changed and the activator are relatively easy to remove. But there are potentially harmful reactions, removal is more difficult.

2. Organic acid flux residue

Organic acid flux (OR) generally refers to the flux in which the solid part of the flux is mainly organic acid. The residues of this flux are mainly unreacted organic acids, such as oxalic acid, succinic acid, etc. and their metals. salts. Most of the so-called colorless no-clean fluxes on the market are of this type. They are mainly composed of polybasic organic acids, including compounds that do not contain halide ions at room temperature, and can generate halide ions when soldering at high temperatures, sometimes including a very small amount of the polar resins, the most difficult to remove is the salts formed by organic acids and solders, which have strong adsorption properties and poor solubility. Larger amounts of these residues and halide salts are produced when water-soluble fluxes are used in the PCBA assembly process, but due to timely aqueous cleaning, such residues can be greatly reduced.

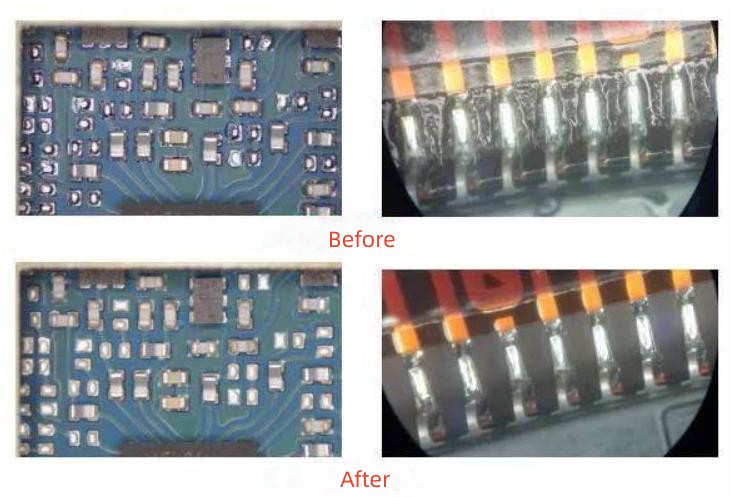

3. White residue

White residues are common contaminants on PCBAs and are generally found after PCBA cleaning or after assembly for a period of time. Many aspects of the PCB assembly process can cause white residue.

The self-color pollutants of PCBA are generally by-products of flux, but the poor quality of PCB, such as the strong adsorption of solder mask, will increase the chance of white residues. Common white residues are polymerized rosin, unreacted activator, and lead chloride or bromide, which is the reaction product of flux and solder. After these substances absorb moisture, the volume expands, and some substances also undergo hydration reaction with water, and the white residue becomes more and more obvious. It is extremely difficult to remove these residues by adsorption on the PCB. Natural rosin is prone to a large number of polymerization reactions in the welding process. If overheating or high temperature for a long time, the problem will be more serious. This process is confirmed from the infrared spectrum analysis results of rosin and residues on the PCB surface before and after the soldering process.

4. Adhesive and oil pollution

In the PCBA assembly process, some yellow glue and red glue are often used, which are used to fix components. However, due to process inspection, the electrical connection parts are often stained. In addition, the residue peeled off after the pad protection tape will seriously affect the electrical connection performance. In addition, some components, such as small potentiometers, are often coated with too much lubricating oil, which will also contaminate the PCBA board surface. The residue of such pollution is often insulated, which mainly affects the electrical connection performance, and generally does not cause corrosion, leakage, etc. failure problem.

Sign In

Sign In Join Free

Join Free