The Main Process of PCBA Testing

Speaking of PCB, everyone is familiar with it, so do you know what PCBA is? PCBA refers to the assembly of PCB boards with SMT assembly, DIP plug-ins, and testing to make a finished product. We can understand that it is a finished printed circuit board. PCBA testing refers to the testing of IC programming, circuit continuity, current, voltage, pressure and other aspects of the PCBA board. There are many uncontrollable factors in the production process of PCB Assembly. It is difficult to ensure that the PCBA is an intact product. PCBA testing is a necessary link to strictly control the quality of shipments. Next, we will introduce the main process of PCBA testing.

1. What tests are included in the PCBA testing

According to diverse customer requirements of their products , PCBA test will be different. PCBA test mainly includes ICT online test, FCT function test, burn-in test.

2. The process of PCBA testing

PCBA test generally formulates a specific test process according to the customer's test plan. The basic PCBA test process is as follows:

Program burning→ICT test→FCT test→aging test

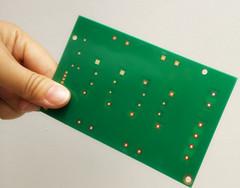

a. Program burning

After the PCBA board completes the front-end welding process, the engineer begins to program the microcontroller in the PCBA board, so that the microcontroller can achieve specific functions.

(Program burning)

The ICT test mainly realizes the test of the open circuit, short circuit and the welding of electronic components of the PCBA board through the test probe contacting the test point of the PCBA. The ICT test has high accuracy, clear instructions, and a wide range of uses.

(ICT test)

The FCT test can test the PCBA's environment, current, voltage, pressure and other parameters. The content of the test is relatively comprehensive, which can ensure that the various parameters of the PCBA board meet the designer's design requirements.

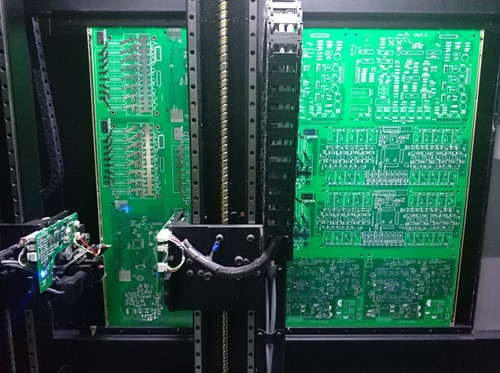

d. Aging test

The aging test can ensure the stability of the product by continuously energizing the PCBA board, simulating the user's use scenario, detecting some difficult-to-find defects, and inspecting the service life of the product.

(Aging test)

After the PCBA has undergone a series of PCBA tests, the PCBA board without problems can be labeled with qualified labels, and finally can be packaged and shipped.

We PCBbee believe that PCBA testing is an indispensable and important link to ensure PCBA quality. It determines PCBA performance, controls PCBA boards quality, reduces after-sales and repair rates, makes our customers more trustworthy, and promotes win-win cooperation between we enterprises and our customers. Any more questions about PCBA testing, please feel free to contact us at service@pcbbee.com, we will reply quickly.

Sign In

Sign In Join Free

Join Free