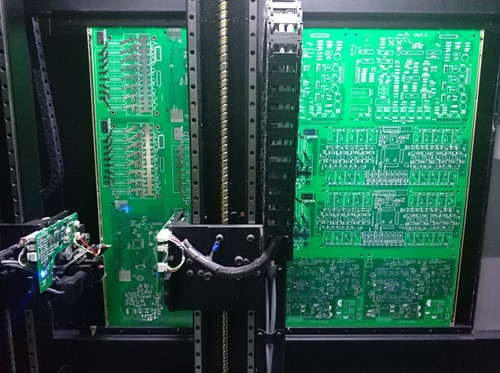

Why double-sided assembled boards increase manufacturing costs?

Frist let’s look at SMT boards.

Putting components on both sides means you have to take two passes through manufacturing. First one side gets stenciled and then goes to pick-and-place machine, then to solder reflow oven, and finally inspection. And then we have to repeat the entire process for the second side of the board. So we’ve essentially doubled the manufacturing effort.

Second, let’s consider mixed-technology boards.

These always require two different processes: one for the SMT components and one for the through-hole components. But it’s still best to put all of the components on the same side. This means we can do a regular SMT process, followed by a regular through-hole process with manual or automatic insertion, wave soldering, and inspection. But if it’s really not possible to get all the components on one side, then the second-best approach is to place all SMT components on one side and all through-hole components on the other. But with a double-sided assembled board, the through-hole side will need special fixture or hand-soldering with higher cost and lower throughput.

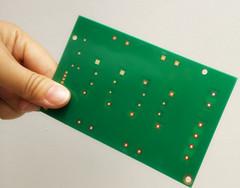

Finally, let’s consider through-hole boards.

With all components on one side, we need just one pass through the standard thru-hole manufacturing process. If we have a second side we go through the process a second time but this time the board can’t go through wave solder oven. So we have to do selective soldering or hand soldering. Again, higher cost and lower throughput.

Double sided assembled boards are fine when they are necessary. But often, spending a little more time on the design and layout can eliminate the need for the second side, and save a lot of money in the manufacturing costs over life of the product.

For more information about PCBA service, please contact us at service@PCBbee.com, we will reply within 2 hours!

Sign In

Sign In Join Free

Join Free