Blog > Detail

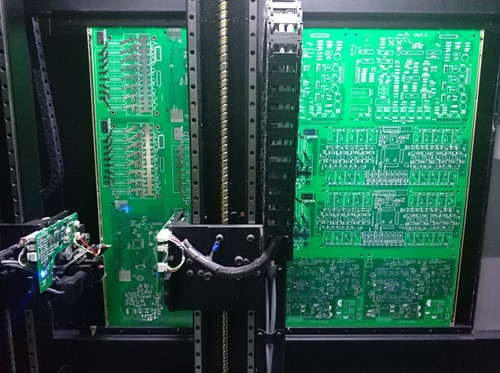

How SMT component packages affect manufacturing?

Time: 2020-11-18 View: 2789

Let’s talk about how the packaging of SMT components affects our PCBA manufacturing process.

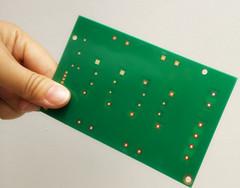

The most common packaging choice is tape and reel. A reel can hold thousands of small parts. For hundreds of larger ones, if you don’t need that many components some distributors will break up a manufacturer’s standard reel to create mini reels with a custom numbers of parts or you can get cut tape with ten to several hundred components per strip. Tubes are another option and trays are popular for larger components and finally some components are sold in bulk.

Reels are easiest for manufacturers to use, they are easy to load into the SMT pick-and-place machine, they hold many parts so they don’t need much intervention once loaded and when they do need to be changed, this can be done without stopping the line, so they are the obvious choice for high-volume production. Reels make sense for lower volume production as well since you can get a reel of five thousand passives for less than $10, it just doesn’t make sense to buy smaller quantities and less convenient packaging, in fact, it might actually cost you more. Reels come with a leader a section of tape that has no parts on it for starting into the automated feeder. If you don’t have this leader you’ll waste these first parts in the machine. How many parts depends on the machine cut.

Tape doesn’t have a leader so you need to allow for waste parts on each tape, if you want to use it in an automated feeder. Or we could take this time to add a leader to every tape, but in manufacturing, time is money. Some machine can use the tray feeder to pick components from cut tape as well as from traits. Trays and tape have lower capacity than reels and need to be changed more often, stopping the line if they’re changed manually. Tubes also need to be changed frequently. A multi tube magazine cuts down on the handling but takes up the space of several reels which is a problem for boards with a lot of different part types. Sometimes we load them into trays for automated placement.

Our pick-and-place lines and production teams are flexible enough so that we can work with any packaging types that our customers supply. Not all contract manufacturers can do this. It pays to work with your manufacturing partner and understand how your choice of component packaging affects the PCB assembly manufacturing process reliability and cost.

For more information of PCB assembly service, please contact us at service@PCBbee.com , we will response in 2 hours.

The most common packaging choice is tape and reel. A reel can hold thousands of small parts. For hundreds of larger ones, if you don’t need that many components some distributors will break up a manufacturer’s standard reel to create mini reels with a custom numbers of parts or you can get cut tape with ten to several hundred components per strip. Tubes are another option and trays are popular for larger components and finally some components are sold in bulk.

Reels are easiest for manufacturers to use, they are easy to load into the SMT pick-and-place machine, they hold many parts so they don’t need much intervention once loaded and when they do need to be changed, this can be done without stopping the line, so they are the obvious choice for high-volume production. Reels make sense for lower volume production as well since you can get a reel of five thousand passives for less than $10, it just doesn’t make sense to buy smaller quantities and less convenient packaging, in fact, it might actually cost you more. Reels come with a leader a section of tape that has no parts on it for starting into the automated feeder. If you don’t have this leader you’ll waste these first parts in the machine. How many parts depends on the machine cut.

Tape doesn’t have a leader so you need to allow for waste parts on each tape, if you want to use it in an automated feeder. Or we could take this time to add a leader to every tape, but in manufacturing, time is money. Some machine can use the tray feeder to pick components from cut tape as well as from traits. Trays and tape have lower capacity than reels and need to be changed more often, stopping the line if they’re changed manually. Tubes also need to be changed frequently. A multi tube magazine cuts down on the handling but takes up the space of several reels which is a problem for boards with a lot of different part types. Sometimes we load them into trays for automated placement.

Our pick-and-place lines and production teams are flexible enough so that we can work with any packaging types that our customers supply. Not all contract manufacturers can do this. It pays to work with your manufacturing partner and understand how your choice of component packaging affects the PCB assembly manufacturing process reliability and cost.

For more information of PCB assembly service, please contact us at service@PCBbee.com , we will response in 2 hours.

Sign In

Sign In Join Free

Join Free