Blog > Detail

Why through-hole technology is not dead?

Time: 2020-11-10 View: 2577

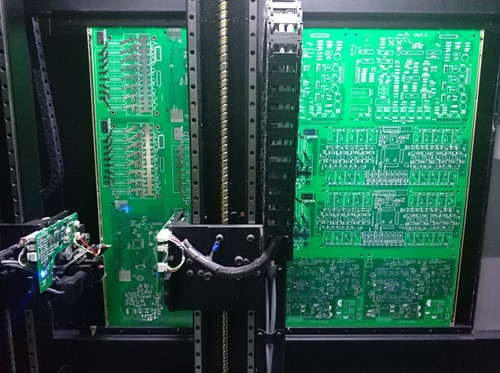

Most contract manufacturers concentrate on their surface mount technology capabilities for PCB assembly. The SMT lines can be almost completely automated to run a high volume of boards with little human intervention and low cost per board. Through hole assembly whether automated or manual is a slower process. It takes resources away from the high-volume business that many manufacturers prefer. The customers also prefer SMT for the size as well as assembly cost.

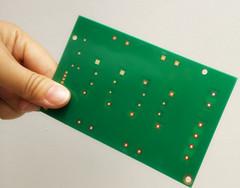

So you might think that through-hole parts are old-fashioned and destined to fade away. Indeed most modern ICs aren’t even available as a through-hole option. But through-holes are not going away anytime soon. At PCBbee even though only about 20% of the parts we buy are through-hole, nearly 90% of the board’s we run our mix technology combination of through-hole and SMT. One reason is that nearly half of our board assemblies are for power supplies which use capacitors inductors and transformers to transfer energy. The size of these components is proportional to the energy that they can store. So for a power supply, we need some fairly large and heavy components. That means through-hole technology.Through-hole components are held in place by the pins as well as the solder, so you get a much stronger and more reliable mechanical bond than with surface mount (SMT) components that have only the solder to hold them in place.

We make other things than power supplies, but these boards are also used in industrial medical and commercial equipment where reliability is important. So things like customer accessible connectors that have to withstand stress as cables are connected and removed are likely to be through-hole components. Some industrial connector types such as BNC aren’t even offered as surface mount.

Through-hole provides the necessary bond string. If your contract manufacturer is focused on higher volume SMT business, it’s important for you to understand how they will handle through-hole components when you need them. At PCBbee we run mix technology boards every day and so we continuously hone our PCB assembly ability to produce boards with through-hole components at a reasonable cost and high quality.

Contact us at service@PCBbee.com to learn more, we will response within 2 hours.

So you might think that through-hole parts are old-fashioned and destined to fade away. Indeed most modern ICs aren’t even available as a through-hole option. But through-holes are not going away anytime soon. At PCBbee even though only about 20% of the parts we buy are through-hole, nearly 90% of the board’s we run our mix technology combination of through-hole and SMT. One reason is that nearly half of our board assemblies are for power supplies which use capacitors inductors and transformers to transfer energy. The size of these components is proportional to the energy that they can store. So for a power supply, we need some fairly large and heavy components. That means through-hole technology.Through-hole components are held in place by the pins as well as the solder, so you get a much stronger and more reliable mechanical bond than with surface mount (SMT) components that have only the solder to hold them in place.

We make other things than power supplies, but these boards are also used in industrial medical and commercial equipment where reliability is important. So things like customer accessible connectors that have to withstand stress as cables are connected and removed are likely to be through-hole components. Some industrial connector types such as BNC aren’t even offered as surface mount.

Through-hole provides the necessary bond string. If your contract manufacturer is focused on higher volume SMT business, it’s important for you to understand how they will handle through-hole components when you need them. At PCBbee we run mix technology boards every day and so we continuously hone our PCB assembly ability to produce boards with through-hole components at a reasonable cost and high quality.

Contact us at service@PCBbee.com to learn more, we will response within 2 hours.

Sign In

Sign In Join Free

Join Free