Blog > Detail

How to choose a surface finish for a PCB

Time: 2020-10-26 View: 1541

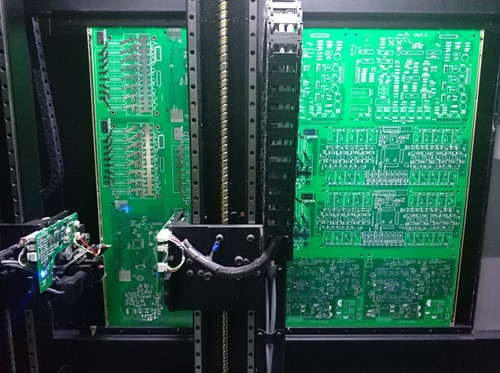

Every bare board gets some sort of surface finish to protect the copper traces from oxidation until the board can be populated and soldered to create your finished PCB assembly. Let’s take a quick look at four of the most common lead-free surface finishes and when to use them. The least expensive finish is HASL, or hot air surface leveling. The board is dipped in molten solder which has been blown off, or leveled, with an air knife, leaving a layer of solder on the copper traces. But the surface is not perfectly level. This would cause significant solder-ability issues with small surface mount components. HASL is a good economical choice if you’re using through-hole or larger SMT components, but if your board uses smaller or fine-pitch SMT components… smaller than 0805 or SOIC…we recommend surface finishes called immersion coatings.

In an immersion coating, a very flat layer of metal just a few molecules thick is deposited on the copper traces using a chemical process. Tin is the least expensive option for immersion coating. Unfortunately, tin and copper form a battery and this means that the tin starts to tarnish as soon as it’s deposited on copper. Too much tarnish leads to lower quality solder joints and poor yields in PCB assembly. So you need to solder immersion tin boards within about 30days. Immersion tin is a pretty good choice for high-volume production where you’ll use large batches of boards very quickly.

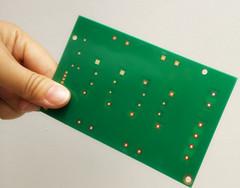

If you don’t have that kind of volume you can consider immersion silver. Silver is more expensive than tin, but it doesn’t react with the copper. However it does tarnish when exposed to air. So boards need be stored in anti-tarnish packaging to slow the reaction. Immersion silver boards can have a shelf life of 6 to 12 months with proper storage. Once you take the board out of the packaging, it should go through solder reflow in about 24 hours depending on your air quality and humidity. You can see the difference between the properly stored board and one that’s been exposed to air.

Finally we have ENIG, or electroless nickel immersion gold. It is chemically-deposited nickel followed by a layer of gold. The nickel provides a non-reactive barrier between the gold and the copper traces. ENIG finish has excellent surface planarity and shelf-life of several years. It also has better solder ability than tin or silver, producing higher yields and consistently better solder joints. ENIG is the most expensive of these options adding up to five percent to the cost of bare boards. But it also keeps labor costs low by reducing the need for rework due to solder issues. And it helps us ensure more reliable products with consistently high-quality solder joints. At PCBbee, we have been trending towards ENIG for almost all of our SMT work. We do a lot of low- to high-volume runs in a high-mix setting.

For more information about PCB assembly service, please contact us service@PCBbee.com, we will response in half day.

In an immersion coating, a very flat layer of metal just a few molecules thick is deposited on the copper traces using a chemical process. Tin is the least expensive option for immersion coating. Unfortunately, tin and copper form a battery and this means that the tin starts to tarnish as soon as it’s deposited on copper. Too much tarnish leads to lower quality solder joints and poor yields in PCB assembly. So you need to solder immersion tin boards within about 30days. Immersion tin is a pretty good choice for high-volume production where you’ll use large batches of boards very quickly.

If you don’t have that kind of volume you can consider immersion silver. Silver is more expensive than tin, but it doesn’t react with the copper. However it does tarnish when exposed to air. So boards need be stored in anti-tarnish packaging to slow the reaction. Immersion silver boards can have a shelf life of 6 to 12 months with proper storage. Once you take the board out of the packaging, it should go through solder reflow in about 24 hours depending on your air quality and humidity. You can see the difference between the properly stored board and one that’s been exposed to air.

Finally we have ENIG, or electroless nickel immersion gold. It is chemically-deposited nickel followed by a layer of gold. The nickel provides a non-reactive barrier between the gold and the copper traces. ENIG finish has excellent surface planarity and shelf-life of several years. It also has better solder ability than tin or silver, producing higher yields and consistently better solder joints. ENIG is the most expensive of these options adding up to five percent to the cost of bare boards. But it also keeps labor costs low by reducing the need for rework due to solder issues. And it helps us ensure more reliable products with consistently high-quality solder joints. At PCBbee, we have been trending towards ENIG for almost all of our SMT work. We do a lot of low- to high-volume runs in a high-mix setting.

For more information about PCB assembly service, please contact us service@PCBbee.com, we will response in half day.

Sign In

Sign In Join Free

Join Free