Reasons for PCB Assembly Defect

1. Layout Design Issues:

(1) Bad package design;

(2) Layout too close leads to connection and dislocation.

(3) The serious asymmetry of copper foil on SMT pad or large area copper cladding lead to poor soldering, tombstone and component shift.

(4) The via on the pad lead to poor soldering.

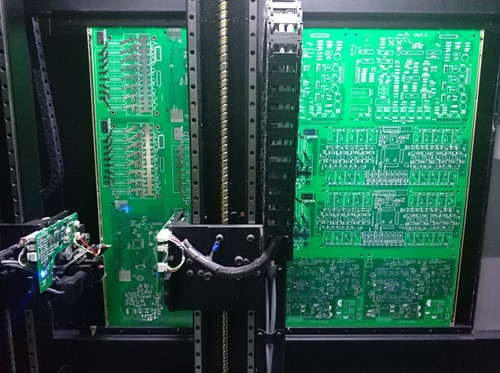

(5) PCB board is too big, which may lead to warping, and then lead to PCB assembly defect.

2. Poor Incoming Materials:

(1) Cold soldering caused by oxidation of components and PCB;

(2) PCB board itself is short-circuited, open-circuited, slightly short and slightly open.

(3) PCB board warping, the national standard requires the degree of warping less than 0.75%, the general requirements are 0.5%, depending on the size of the board and PCBA manufacturer’s processing capacity;

(4) Improper surface treatment of PCB and uneven pad;

(5) Components can not withstand high temperature, resulting in rupture, deformation and damage.

(6) PCB stencil is too thick or thin which leads to poor welding and connection.

3. PCBA process:

(1) Poor solder paste and unreasonable setting of over-furnace temperature curve lead to poor soldering and false welding.

(2) The unreasonable setting of over-furnace temperature curve leads to poor soldering, connection and false welding.

At present, the methods for PCB assembly testing mainly are:

(1) AOI Testing

Test Principle: Image Contrast

(2) ICT Testing

Test Principle: Similar to Multimeter Principle, Test Value

(3) Manual Detection

Manual Testing in Quality Departments

(4) Functional testing

The status of PCB assembly testing in the industry:

At present, no company can guarantee to test out all the defective products, because each test has its shortcomings, and can not test out all the defective products. However, if we can pass the above test, the probability of problems is very small, but in the process of product development and design, we should consider the test problem as far as possible. Component selection, schematic design. PCB design, software settings, etc. can reduce the rate of poor performance.

PCBbee Can offer PCBA price in 2hours, Quote Now!

Sign In

Sign In Join Free

Join Free