Do you really know PCB? Take you to unlock the secret of PCB board!

1. Who is noble? The secret of PCB color

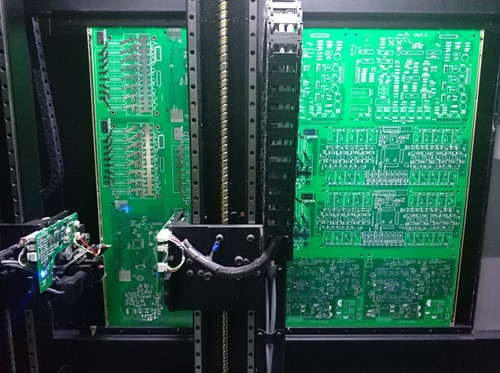

Many DIY players will find that PCB colors used in various pcb card products in the market are dazzling. The more common PCB colors are black, green, blue, yellow, purple, red and brown. Some PCB manufacturers have also developed PCBs with different colors such as white and pink.

In the traditional impression, black PCB seems to be positioned at the high end, while red, yellow and other low-end dedicated, is that so? We know that both sides of PCB are copper coatings. In the production of PCB, copper coatings will eventually be smooth and unprotected. Although the chemical properties of copper are not as active as those of aluminium, iron and magnesium, it is easy to oxidize when pure copper contacts with oxygen in the presence of water. Oxygen and water vapor exist in the air, so the surface of pure copper will oxidize quickly after contacting with air. Because the thickness of copper layer in PCB is very thin, the oxidized copper will become a bad conductor of electricity, which will greatly damage the electrical performance of PCB.

To prevent copper oxidation, to separate the welded and non-welded parts of PCB during welding, and to protect the surface of PCB, engineers invented a special coating. The coating can be easily applied on the surface of PCB, forming a protective layer with a certain thickness, and blocking the contact between copper and air. This coating is called solder-resist layer, and the material used is solder-resist ink.

Since it's called ink, there must be different colors. Yes, the original solder-resist ink can be made colorless and transparent, but PCB often needs to print small text on the board for easy maintenance and manufacture. Transparent solder resist ink can only show PCB background color, so whether it is manufacturing, maintenance or sales, the appearance is not good enough. So engineers added various colors to the solder resist ink and eventually formed black or red or blue PCBs.

2. Black PCB is difficult to see the alignment, which brings difficulties for maintenance.

From this point of view, the color of PCB has nothing to do with the quality of PCB. The difference between black PCB and blue PCB, yellow PCB and other colors of PCB is that the color of the solder resistance ink on the final brush is different. If the PCB design and manufacturing process is exactly the same, the color will not have any impact on performance, nor will it have any impact on heat dissipation. As for black PCB, it is not very convenient to manufacture and use because its surface wiring is almost completely covered, resulting in great difficulties for later maintenance. Therefore, in recent years, people have gradually reformed to use dark green, dark brown, dark blue and other solder-resist ink instead of using black solder-resist ink, in order to facilitate manufacturing and maintenance.

At this point, you have basically understood the problem of PCB color. The reason for the statement that "color represents high-end or low-end" is that manufacturers like to use black PCB to manufacture high-end products and use red, blue, green, yellow and other low-end products. To sum up, the product gives the meaning of color, not the meaning of color.

3. What are the advantages of using precious metals such as gold and silver in PCB?

The colour is clear, and now the precious metals on PCB! When some PCB makers publicize their products, they will especially mention that their products adopt special processes such as gold plating and silver plating. So what's the use of this process?

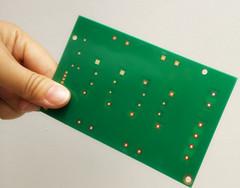

The PCB surface needs welding components, which requires a part of the copper layer to be exposed for welding. These exposed copper layers are called pads, which are usually rectangular or circular and have a small area. In the foregoing, we know that the copper used in PCB is very easy to be oxidized, so the only copper that is exposed to the air is the copper on the pad after being painted with solder-resist ink. If the copper on the pad is oxidized, it is not only difficult to weld, but also the resistivity increases greatly, which seriously affects the performance of the final product. So engineers came up with a variety of ways to protect the pad. For example, an inert metal gold plating, or a chemical process to cover the surface with silver, or a special chemical film to cover copper, to prevent contact between the pad and air.

From this point of view, whether gold or silver, the purpose of the process itself is to prevent oxidation and protect the pad, so as to ensure the rate of good products in the next welding process. However, different metals will require the storage time and conditions of PCB used in production plants. Therefore, PCB factories usually use vacuum packaging machine to package PCB before PCB production is completed and delivered to customers to ensure that PCB does not suffer oxidative damage to the greatest extent. And before the final components are welded on the machine, the pcb board manufacturer also needs to check the degree of oxidation of PCB once, eliminate the oxidation of PCB, and ensure the rate of good products. Ultimately, the boards that consumers get have passed all kinds of tests. Even after long-term use, oxidation will almost only occur in the plug-and-pull connection, and has no effect on the pad and the components that have been welded.

Since the resistances of silver and gold are lower, will the use of special metals such as silver and gold reduce the calorific value of PCB?

We know that the biggest factor affecting calorific value is resistance. The resistance is also related to the material of the conductor itself, the cross-sectional area and the length of the conductor. The thickness of metal material on the surface of the pad is even far below 0.01 mm. If the pad is treated by OST (organic protective film), there will be no excess thickness at all. The resistance of such a small thickness is almost equal to zero, or even impossible to calculate. Of course, it will not affect the calorific value.

PCBbee offers high quality PCB service, get an instant PCB price in 1 second, quote now!

Sign In

Sign In Join Free

Join Free