Surface Treatment of PCB--Difference Between Immersion Gold and Plated Gold

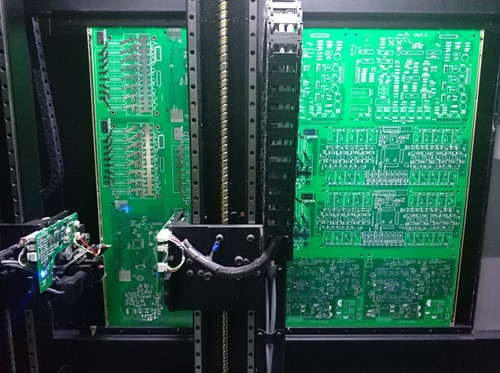

There are several kinds of surface treatment processes for PCB: smooth board (no surface treatment), OSP (organic solder protector, slightly better than rosin), HASL (with lead, lead-free ), gold plated board, Immersion gold board, etc.

We briefly introduce the difference between Immersion Gold and Plated Gold

|

Process |

Appearance |

Weldability |

signal transmission |

Quality |

|

Plated Gold |

Golden White |

Occasional welding defects occur. |

Skin effect is not conducive to the transmission of high frequency signals. |

1.Easy oxidation; 2.Weak bonding resistance. |

|

Immersion Gold |

Golden |

Good |

Skin effect has no effect on signal. |

1.Not easy to oxidize; 2.Strong bonding resistance. |

* Immersion gold are deposited by chemical deposition method. A layer of gold deposits is produced by chemical oxidation-reduction reaction method. Generally, the thickness of the deposits is thicker. It is one of the deposition methods of chemical nickel-gold deposits and can achieve thicker gold deposits.

* Gold plating is based on the principle of electrolysis, also known as electroplating. Other metal surface treatments are mostly electroplated.

In the application of practical products, 90% of the gold pcb board is Immersion gold board, because poor weldability of the plated gold pcb is his fatal shortcoming, and it is also the direct reason that many companies give up the gold plating process!

Immersion Gold process deposits nickel-gold coating on printed circuit surface with stable color, good brightness, flat coating and good weldability. Basically, it can be divided into four stages: pretreatment (degreasing, micro-corrosion, activation, post-immersion), nickel precipitation, gold precipitation, post-treatment (waste gold washing, DI washing, drying). The thickness of gold deposit ranges from 0.025 to 0.1um.

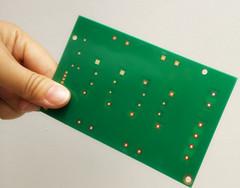

Gold is applied to the surface treatment of circuit boards because of its strong electrical conductivity, good oxidation resistance and long life. Generally, it is used as keyboard, gold finger pcb, etc. The fundamental difference between gold plated board and immersion gold board is that gold plating is hard gold (wear-resistant), while immersion gold is soft gold (not wear-resistant).

1. Deposition of immersion gold is different from that of plated gold. Immersion gold is much thicker than that of plated gold. Immersion gold is golden yellow and yellower than that of gold plating (which is one of the ways to distinguish between plated gold and immersion gold). Plated gold is slightly whiter (the color of nickel).

2. Immersion gold is different from the crystal structure formed by plated gold. Immersion gold is easier to weld than plated gold and will not cause bad welding. The stress of immersion gold board is easier to control, which is more conducive to bonding processing for products with bonding. At the same time, because the immersion gold is softer than the plated gold board, the immersion gold boardis not wear-resistant (the shortcomings of the immersion gold PCB circuit board).

3. There is only nickel and gold on the pad of the immersion gold pcb. In skin effect, the signal transmission is in the copper layer, which will not affect the signal.

4. Immersion Gold is more dense than plated gold and is not easy to oxidize.

5. With the increasing requirement of PCB processing accuracy, the linewidth and spacing have reached less than 0.1mm. Plated Gold is prone to short circuit. Immersion Gold board only has nickel and gold on the welding pad, so it is not easy to produce short circuit of gold wire.

6. Only the pad of immersion gold circuit board has nickel and gold, so the combination of solder resist and copper layer on the circuit is more firm. The spacing will not be affected when the engineer compensate the files.

7. For the PCB with higher requirement, the flatness requirement is better. Immersion Gold is generally used. The smoothness and service life of immersion gold board are better than those of plated gold pcb board.

8. So at present, most factories adopt the process of immersion gold process. However, immersion gold process is more expensive than plated gold process (higher gold content), so there are still a large number of low-cost products using plated gold process (such as remote control board, toy board).

Sign In

Sign In Join Free

Join Free